Digital twinning in aviation yields revolutionary insights

Digital replicas of systems benefit aircraft safety, maintenance, and operations through virtual prototyping, monitoring, and simulations.

By Don Van Dyke

ATP/Helo/CFII. F28, Bell 222

Pro Pilot Canada Technical Editor

An aviation digital twin (DT) is a virtual replica of a physical aircraft and/or its components, created using data from sensors, machine learning, and software analytics, and it’s updated in real-time to reflect the current state of its physical counterpart.

McKinsey & Company note that DTs can help many kinds of organizations simulate real world situations and their outcomes, ultimately allowing them to make better decisions.

The National Business Aviation Association (NBAA) views digital twinning as a transformative technology for aviation, recognizing its potential to significantly enhance aircraft operations, maintenance, repair, and overhaul (MRO), and overall organizational efficiency. DTs bridge physical systems with intelligent virtual replicas which contribute to business aviation in 4 main areas – design, assembly, manufacturing, and operation and maintenance.

According to Grand View Research, the global digital twin market size was estimated at $16.75 billion in 2023, and is projected to grow at a compound annual growth rate (CAGR) of 35.7% from 2024 to 2030.

The aerospace DT market is experiencing significant growth. Investment in digital twins within the aerospace and defense sectors has increased by 40% in the past financial year, representing 2.7% of these organizations’ revenues. This growth is driven by the adoption of advanced technologies like artificial intelligence (AI), which enable real-time data collection and analysis for improved product life cycle management and maintenance.

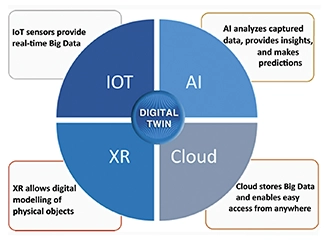

DT technology is a key component of the 4th industrial revolution, driven by 4 key technical advances:

• The Internet of things (IoT) network and big data (extremely large and complex data sets) collected by sensors on connected systems. It allows detailed insights to live performance.

• Advanced analytics (including AI) use big data to predict and simulate future condition or deterioration of monitored assemblies.

• Innovations in virtual reality allowing DTs to improve interpretation of analytics used in critical decision-making.

• Cloud-based computing power and storage capability improves the affordability and availability required to run large-scale digital twin models.

The smallest element of a system that can make use of digital twinning is known as a component or part twin, such as a sensor, switch, or valve. Using virtual replicas of these individual components, it is possible to monitor their performance, simulate real-time conditions, and test their endurance, stability, and efficiency.

Aviation’s drive towards sustainability also adopts DTs as tools to speed innovation of new aircraft types and propulsion systems. Technologies (eg, hydrogen fuel cells and engines, distributed electric propulsion) seek to avoid years of physical test data for qualification.

Virtualization can identify which physical tests remain necessary to achieve certification.

A state of ready-at-first-flight requires extensively explored design, manufacturing, and test spaces to identify a combination that succeeds from the start. Digital twinning can expedite that process.

Honeywell recently demonstrated its ability to upgrade efficiently the current cooling capacity of the Lockheed Martin F-35 Lightning It’s power and thermal management system (PTMS).

A DT was used to combine data from many hours of testing and in-flight experience and controls to optimize system performance, avoiding the risks that otherwise comes with qualifying and fielding a new system that costs billions of dollars without any additional benefit.

Features of digital twinning

In the design and development phase, digital twinning creates virtual replicas of aircraft components and systems to simulate and test different design scenarios, leading to more efficient and innovative designs.

Component or system manufacturing is monitored, and production is optimized in real time, ensuring specifications are met precisely and potential issues are identified before they arise.

Customer experience may also be enhanced through interactions providing clients with a virtual experience of their aircraft, allowing them to see and interact with the design before it is built.

During monitored operations, the DT is updated continuously with data from the physical aircraft, thus allowing predictive maintenance to optimize aircraft performance and reduce downtime.

Quality control compares OEM-made components with their digital counterparts to ensure deviations are detected early, reducing waste and unnecessary rework.

Life cycle management using DTs provides a comprehensive view of the aircraft, from design and manufacturing to operation and decommissioning, ensuring better asset management and value retention.

Approaches to digitally twinning

Aziz Tahiri, vice president of global aerospace and defense at Hexagon, recommends 3 steps when starting to digitize. The first is to decide what should be monitored, how much, and what the extracted early value is likely to be.

The scale of the DT must be considered. Theoretically, it could contain all the real-world data about a part, but does it need to? Hot points (identifying business activities or core expertise in which low yield can be improved). For an OEM or MRO, example processes may involve non-conforming parts and wastage, or injuries on the shop floor.

The second step is to include the people most directly involved with the design, development, operation, or maintenance of the system(s) under review. They know better than anyone what operates reliably and meets goals, and what does not. Their opinions will help to frame what and where to digitize.

The third step is to consider whether to store the collected big data on site or in the cloud. This is a key personal or corporate decision. Every new generation aircraft comes with terabytes of technical information covering every component, part, and software to operate at full capacity. The ability to consume, share, and derive big data insights is invaluable to digital MRO.

MIT Technology Road Mapping, 2024. This diagram illustrates how DTs have evolved over the years regarding their capacity to integrate available data for specific complex systems.

The digital MRO market

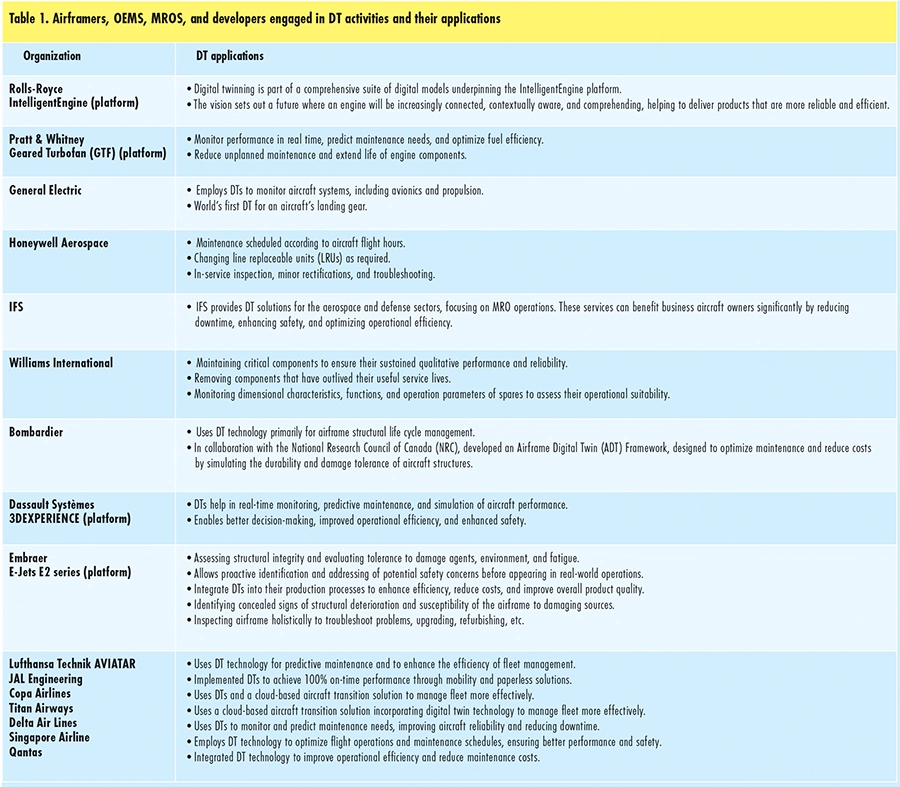

The current digital MRO market is robust – and increasingly so. Table 1 includes several examples of MROs employing digital twinning successfully in advanced predictive and follow-up maintenance. As the technology matures, it is like to scale to smaller, more individualized MRO providers.

Aviation MRO comprises 4 main segments – airframe, engine, components (including avionics, hydraulics, electrical systems), and line maintenance (including minor repairs).

Consulting firm Oliver Wyman reports that the global spend on MRO in 2023 reached approximately $104 billion, and is expected to grow at an annual rate of 1.8% to $124 billion by 2034.

DTs enable MROs to perform predictive maintenance, maximize aircraft availability, and improve overall operational efficiency.

While not itself an MRO, McKinsey & Company has conducted extensive research and surveys on how AI-powered DTs can revolutionize aircraft MRO.

An additional but separate MRO segment regards upgrades and modifications to improve performance or to comply with new regulations, and may be treated in a future article.

DT drivers

Technological development continues to grow at an exponential rate, with new automated technologies emerging to better understand the behavior of multiple systems under different circumstances. The substantial benefits of digital twinning encouraging innovation and adoption include:

Predictive maintenance. DTs allow for real-time monitoring and predictive maintenance, reducing downtime, and extending the lifespan of aircraft

components.

Enhanced safety. Continuous data collection and analysis can identify potential issues before they become critical, leading to more rigorous safety standards and improving overall safety.

Cost savings. Digital twinning facilities collaboration in new product design and development by streamlining certification and optimization processes, avoiding extensive physical testing.

Operational efficiency. Optimized flight routes, fuel consumption, and maintenance schedules lead to cost savings and increased productivity.

Design/manufacturing innovation. Designs can be tested and refined virtually before building physical prototypes, speeding development, supply, and delivery processes.

Improved passenger experience. Personalized services, seamless check-in processes, and enhanced inflight entertainment can significantly improve passenger satisfaction.

Environmental benefits. Reduced fuel consumption and emissions contribute to the aviation industry’s sustainability efforts.

There are several noteworthy considerations which give pause when evaluating the costs and benefits of digital twinning, including:

High initial costs. Implementing DT technology can be expensive, requiring significant investment in software, hardware, and training.

Complex data management. Managing and analyzing large volumes of data can be challenging and requires robust IT infrastructure. Given the interconnected nature of DT systems, associated risks of unauthorized access or data breaches must also be robustly and proactively prevented.

Cybersecurity risks. Increased connectivity and data sharing raise concerns about data breaches and cyber attacks. Encrypting sensitive data is essential to ensure that the data remains unreadable and protected, even if unauthorized access occurs. Advanced encryption standards must be employed to secure both communication systems and data storage.

Maintenance of accuracy. Ensuring the DT remains accurate and current with the physical asset requires constant updates and adjustments.

Operational strain. Integrating DTs into existing systems can be complex and may require significant changes to operational processes.

Ethical concerns. Issues related to data privacy and the ethical use of collected data need to be managed with care.

Conclusion

DTs in aviation represent a radical change in how the industry approaches the design, manufacture, analysis, operation, and maintenance of aircraft. The technology provides real-time, in-depth understanding of aircraft behavior and related processes, creating opportunities for predictive collaboration to improve safety, reliability, efficiency, and economic returns.

DT technology provides a continuous data stream from physical assets (eg, airframe, engines, systems) to digital counterparts. This enables real-time observation and enhanced decision-making, leading to improved operational efficiency, reliability, and life cycle management.

The future of aviation will feature more rigorous safety standards and demands for outstanding performance as it increases the use of DT technologies.

DTs help aviation by providing real-time data and predictive analytics, leading to more informed decision-making and improved operational performance.

An excellent implementation paper for aviation is Digital Twin: Reference Model, Realizations & Recommendations. It was produced by the American Institute of Aeronautics and Astronautics (AIAA), Aerospace Industries Association (AIA), and International Association for the Engineering Modelling, Analysis and Simulation Community (NAFEMS), and is available for free download from various online sources.

The paper highlights a cross-section of real and tangible DT case studies. The paper is intended for those who are interested in the development and implementation of DTs as a means to realize value.

Aeronautical journals and publications like those of the Royal Aeronautical Society (RAeS) and the Council of European Aerospace Societies (CEAS) also provide articles and papers discussing the challenges and opportunities of implementing DTs in aircraft production, operation, and MRO.

Digital twinning increasingly contributes to safe, reliable, effective, and efficient aircraft operation and life cycle management.

Don Van Dyke is professor of advanced aerospace topics at Chicoutimi College of Aviation – CQFA Montréal. He is an 18,000-hour TT pilot and instructor with extensive airline, business and charter experience on both airplanes and helicopters. A former IATA ops director, he has served on several ICAO panels. He is a Fellow of the Royal Aeronautical Society and is a flight operations expert on technical projects under UN administration.

Don Van Dyke is professor of advanced aerospace topics at Chicoutimi College of Aviation – CQFA Montréal. He is an 18,000-hour TT pilot and instructor with extensive airline, business and charter experience on both airplanes and helicopters. A former IATA ops director, he has served on several ICAO panels. He is a Fellow of the Royal Aeronautical Society and is a flight operations expert on technical projects under UN administration.